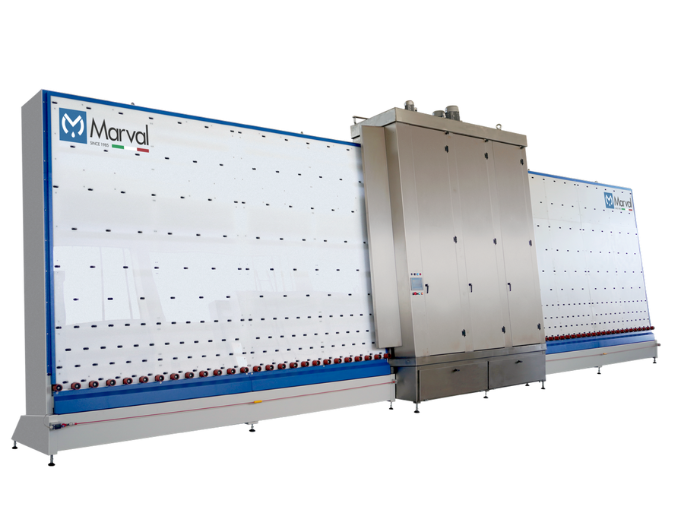

Vertical washing machine “TOP WASH”

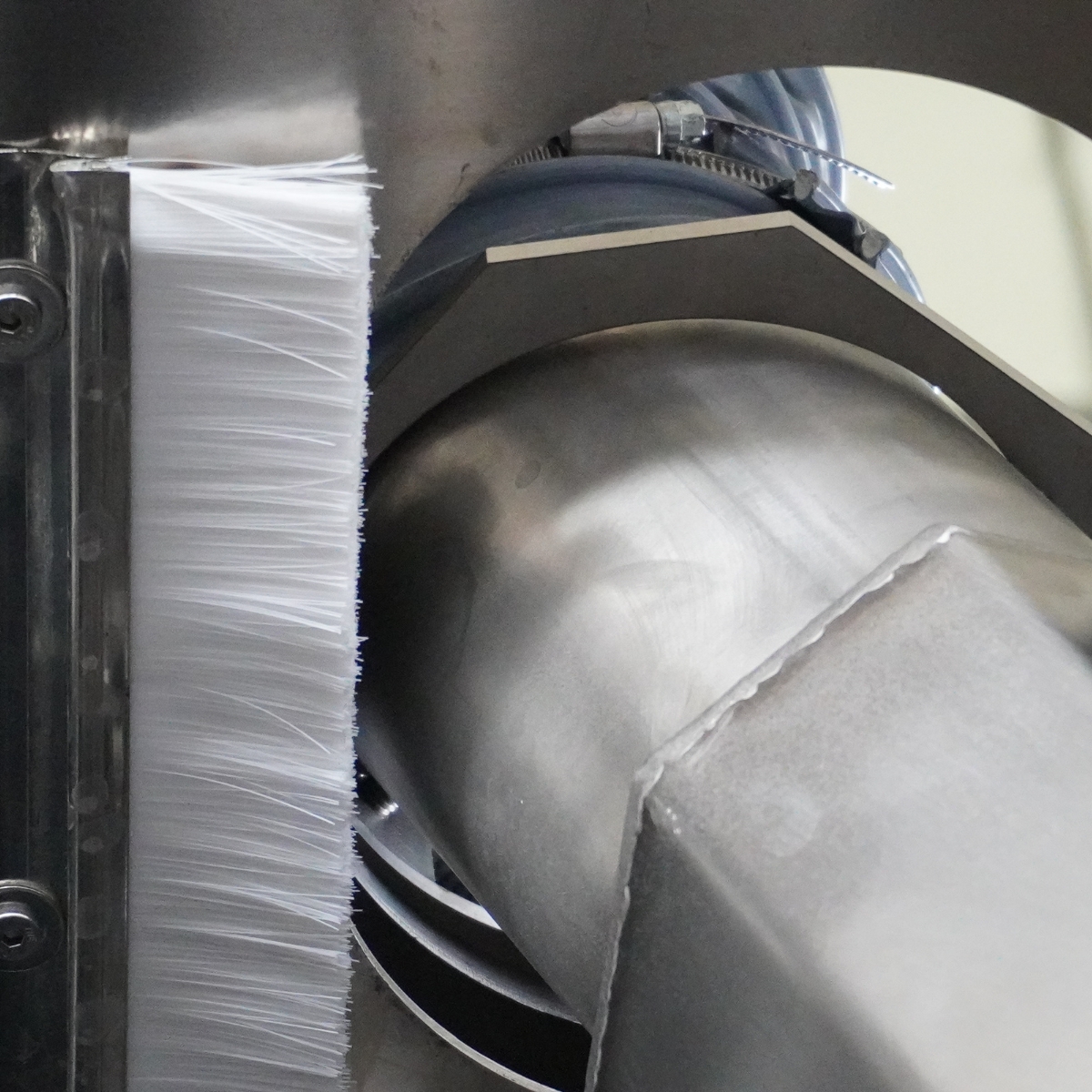

“TOP WASH” series vertical washing machines, made of AISI 304 stainless steel, are the perfect compromise between reliability and durability over time. These are highly efficient solutions thanks to their particularly robust structure, which is crucial in guaranteeing the necessary speed and efficiency to wash sheets ranging from 3 to 50 mm thick (“TOP WASH” version) or up to 20 mm thick (“EASY WASH” version); operation is by six powerful brushes with a 180 mm diameter.

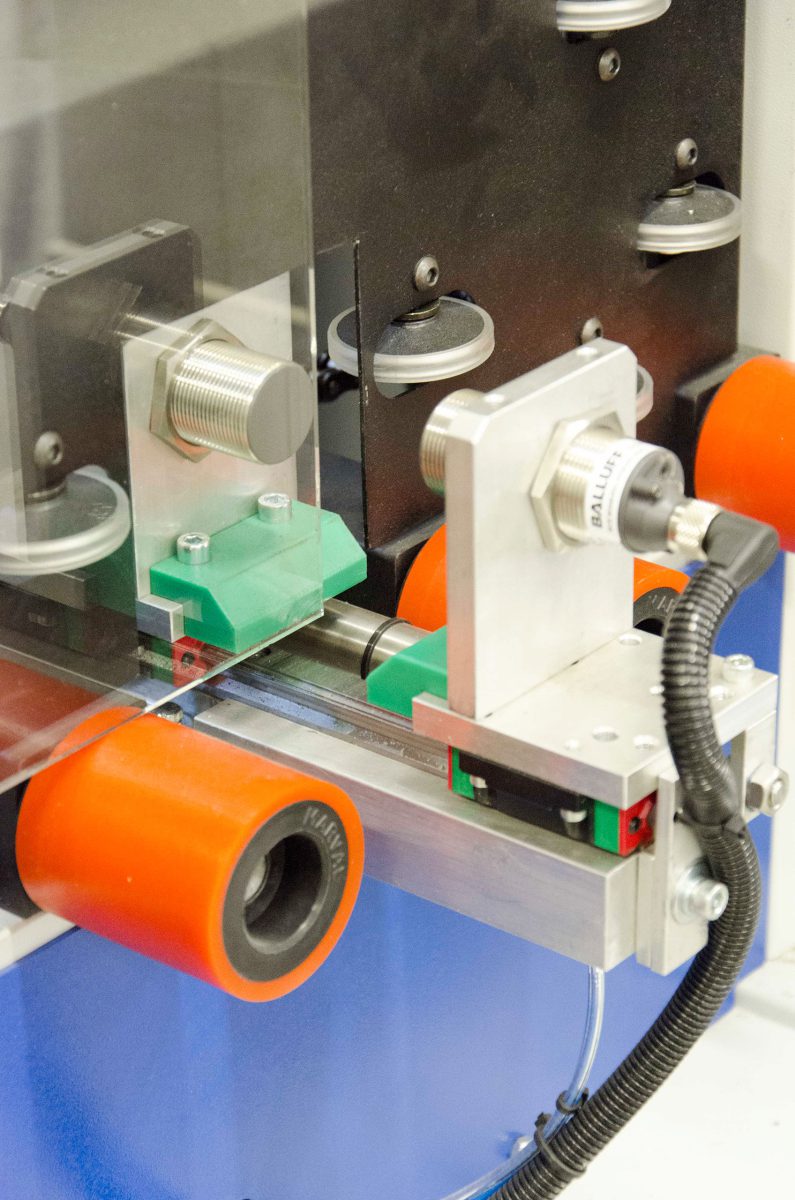

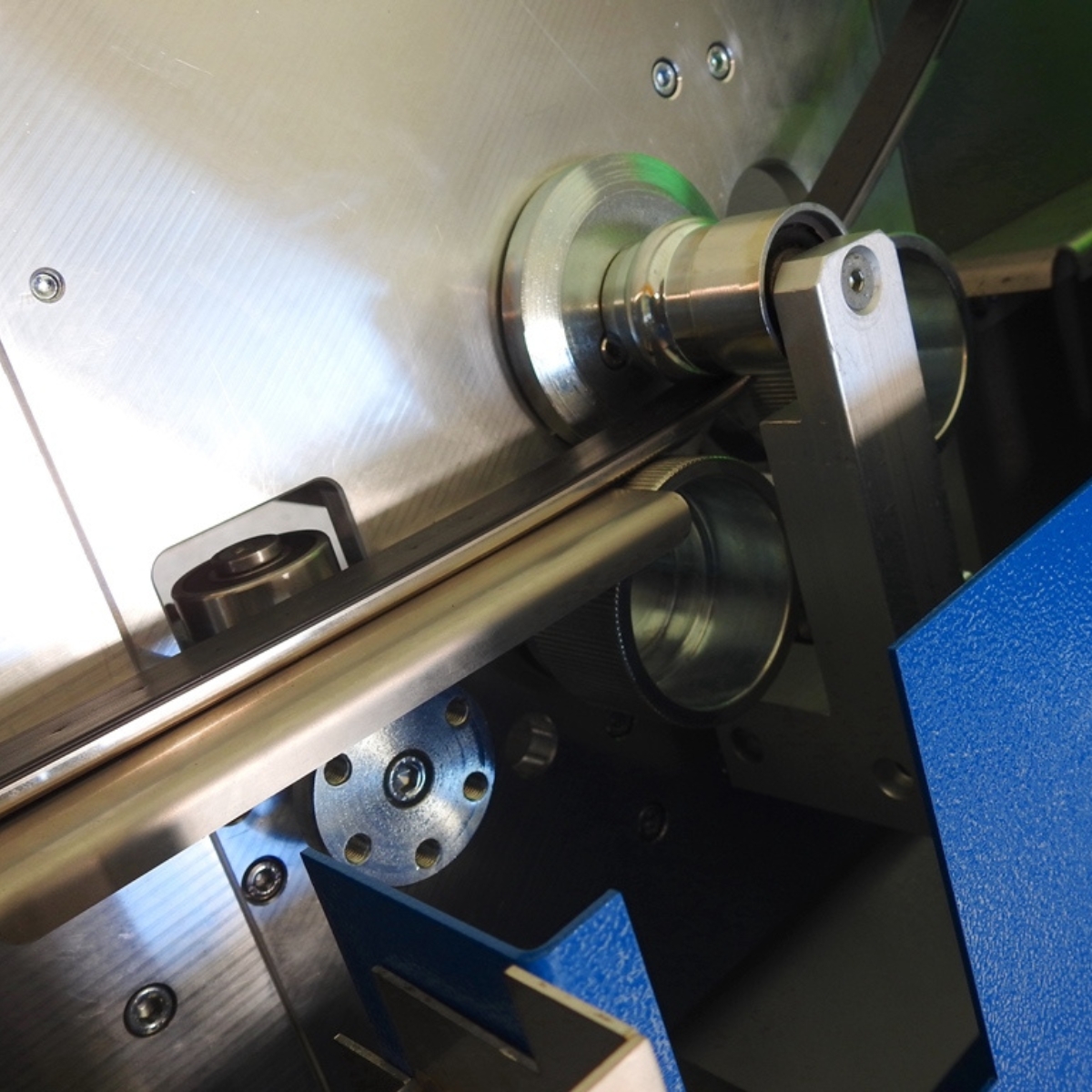

The drive for the glass conveyor, the speed of which can be adjusted via inverter to up to 10 metres a minute, and for the brushes is located on the upper part of the machine.

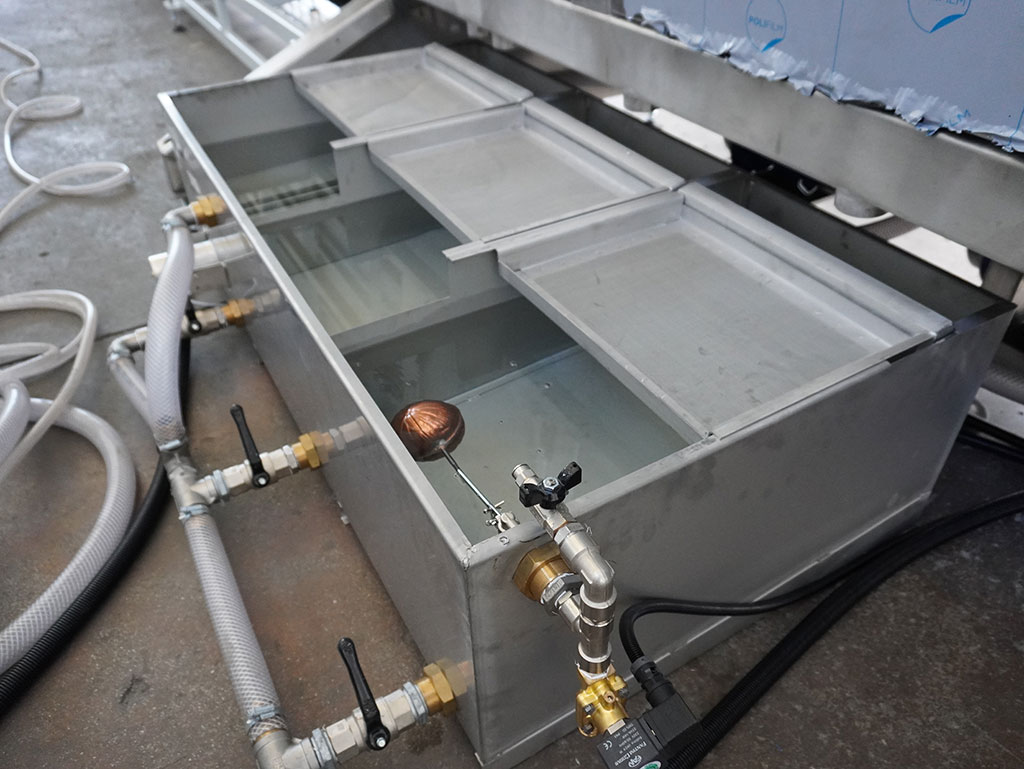

The interior is made entirely of stainless steel, which is the same material used for the three tanks equipped with pumps.

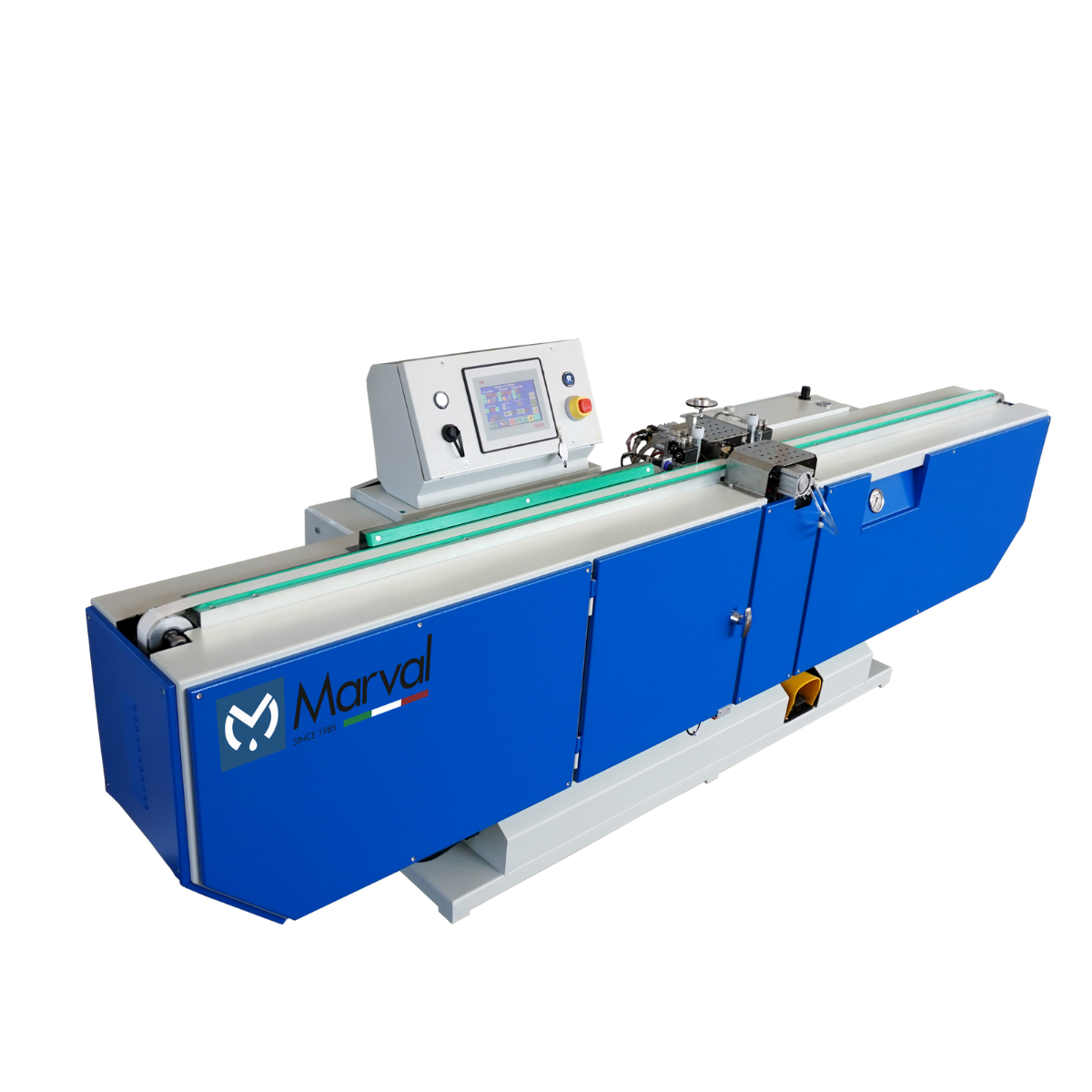

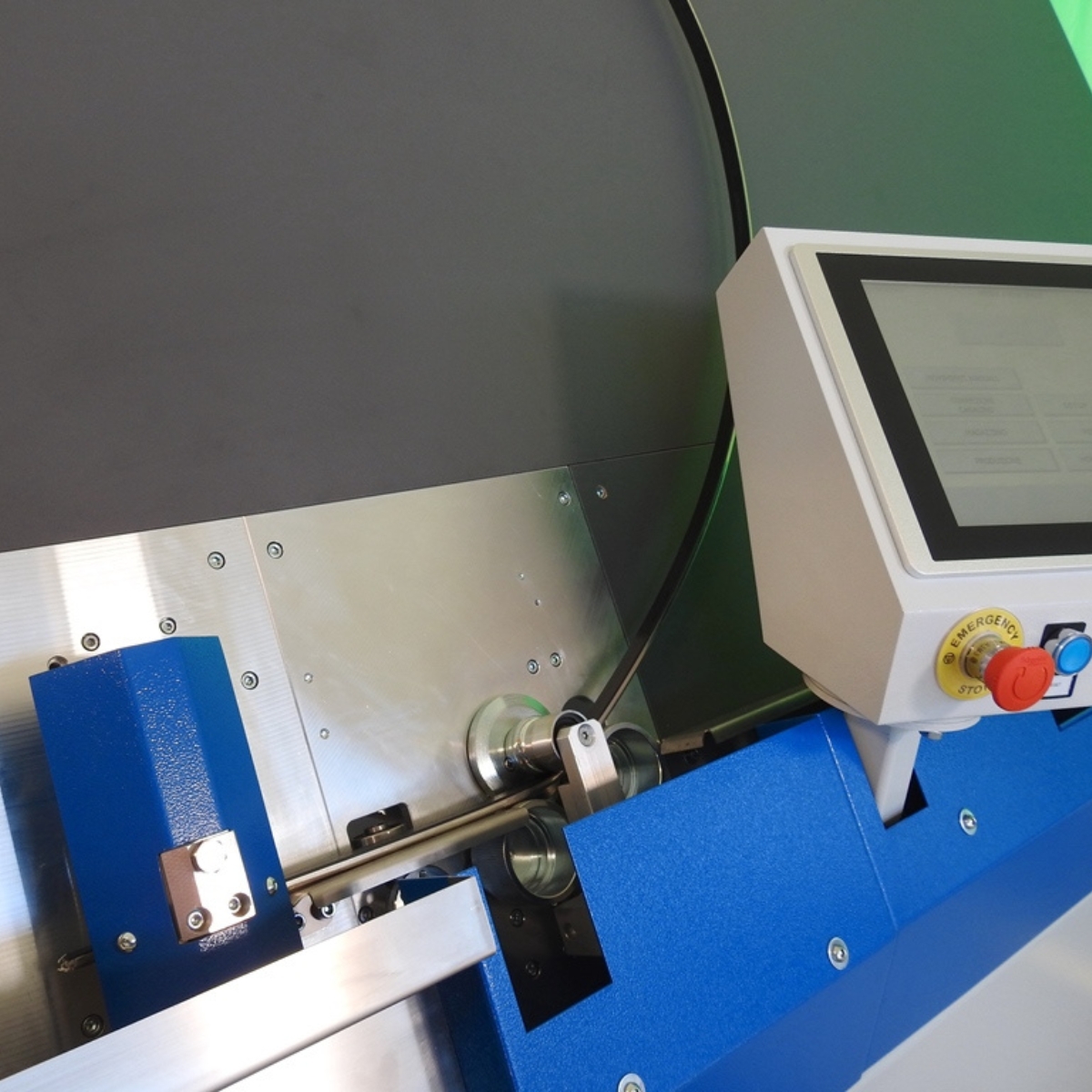

Marval vertical washing machines are structured in three sections: infeed, washing and drying unit and outfeed. They are available in 1,600, 2,000, 2,500, 2,800, and 3,250 mm versions.

The washing process is completely automatic and the PLC equipped with touch screen makes it extremely easy for the operator to run it.