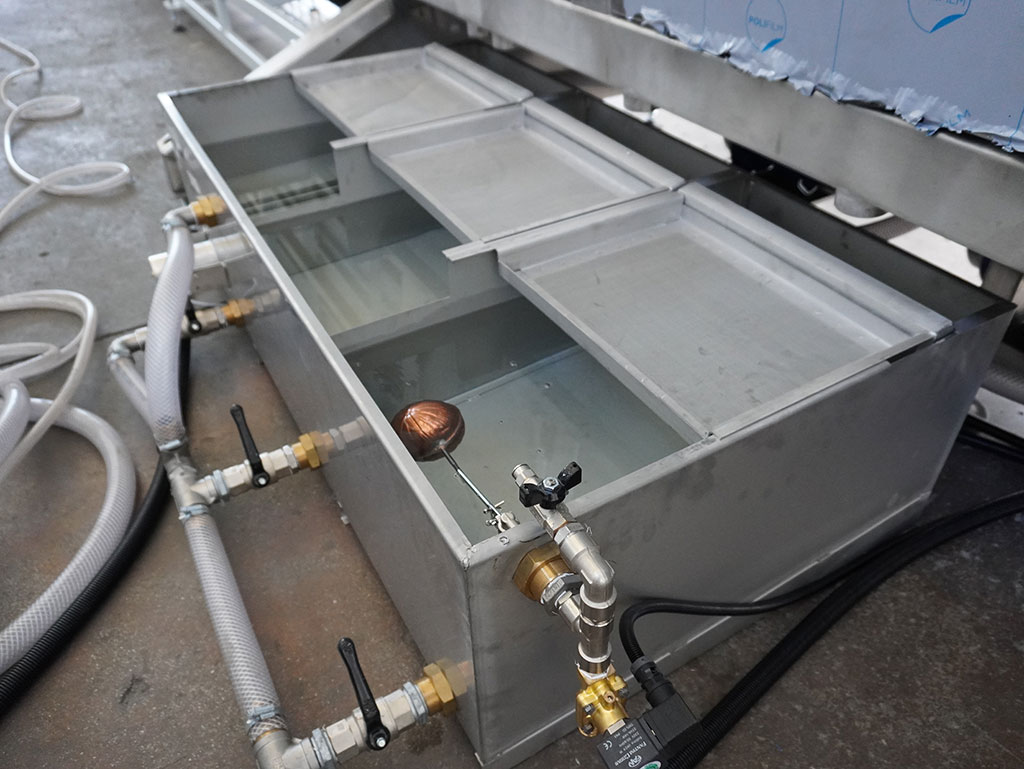

All versions can be equipped with the “GAS PRESS” injection bar featuring:

- gas filling through a special atomisation system located at the bottom of the machine;

- fast and efficient work cycle;

- extremely high fill rate;

- minimal gas leakage.

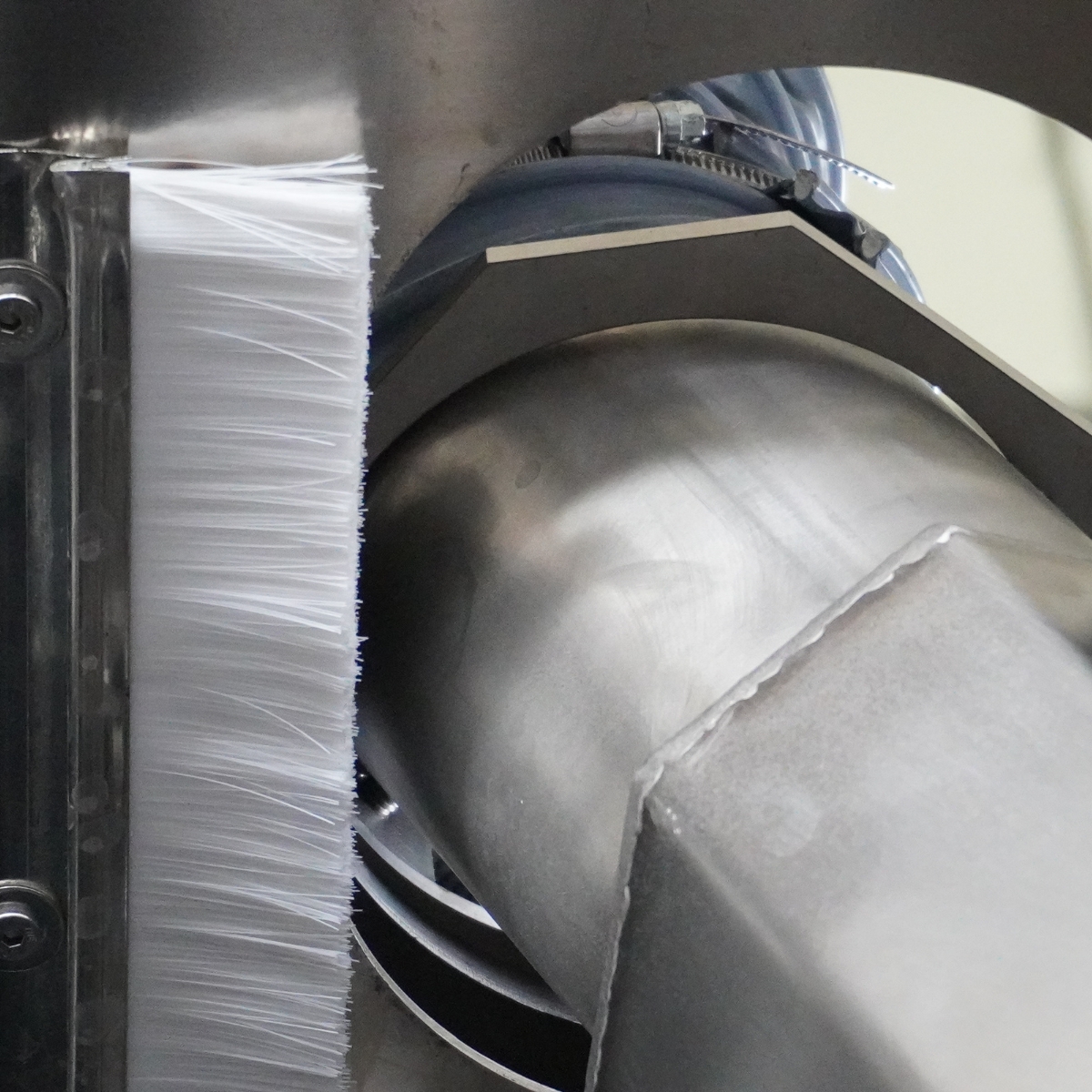

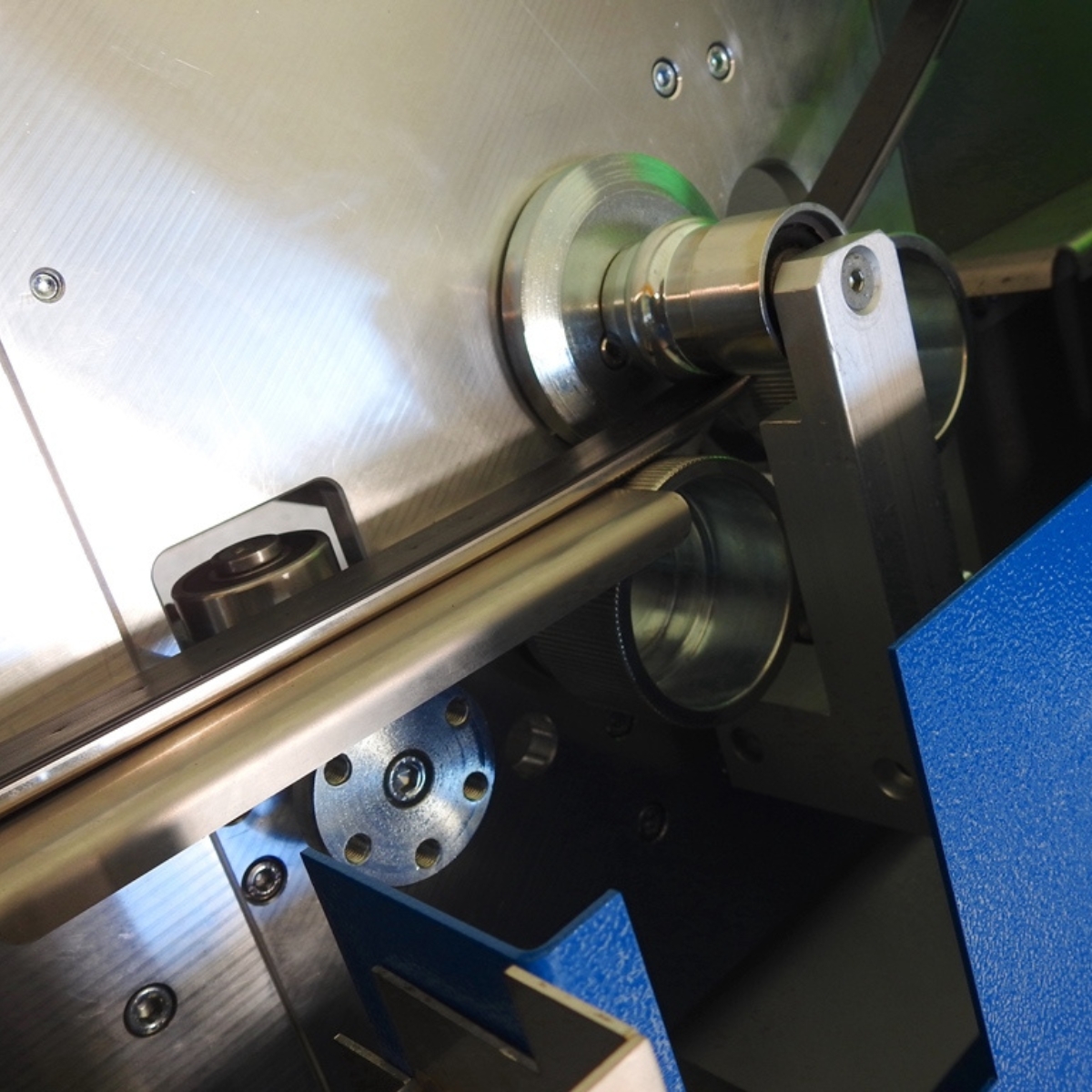

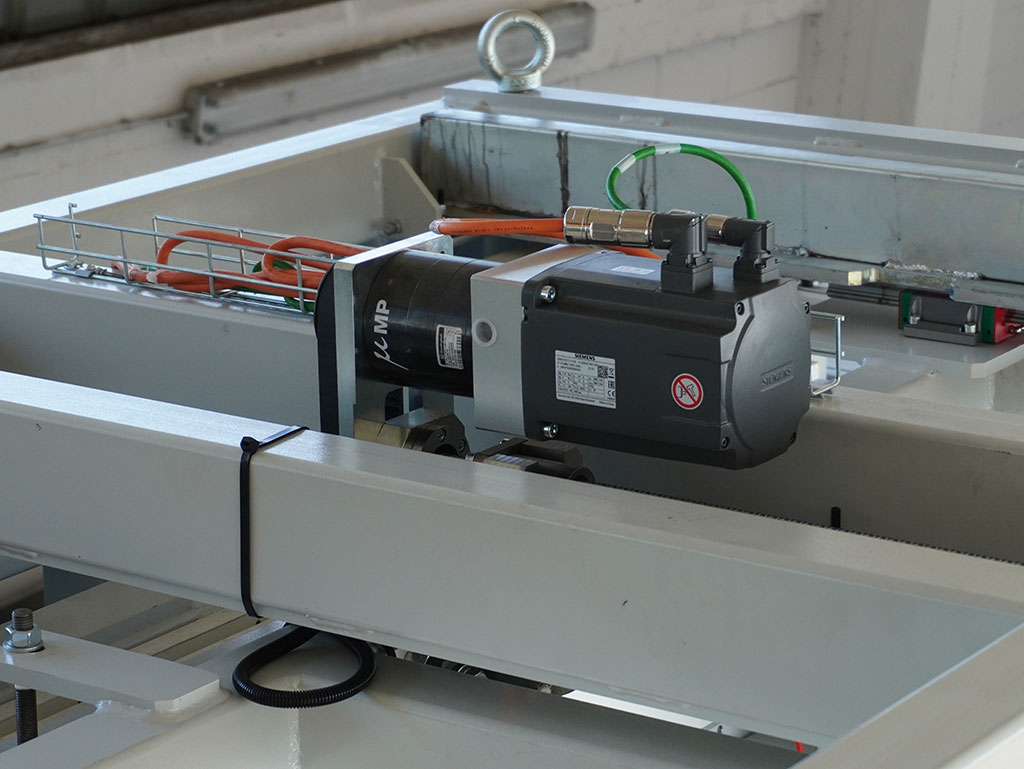

"Brushless" motor modules

The machine’s structure consists of a series of modules, each of which is moved by brushless motors. This guarantees an even pressing force across the entire panel, allowing for perfect adhesion of the sealant and preventing gas leaks.

“GAS PRESS” injection bar (optional)

The bar used to inject gas inside the panel is positioned in the lower part of the machine’s mobile panel. Divided into sectors automatically controlled by solenoid valves, it optimises the amount of gas used, so that it is proportional to the size of the panel and prevents unnecessary waste. This is all done without affecting the quality of the insulating glass.

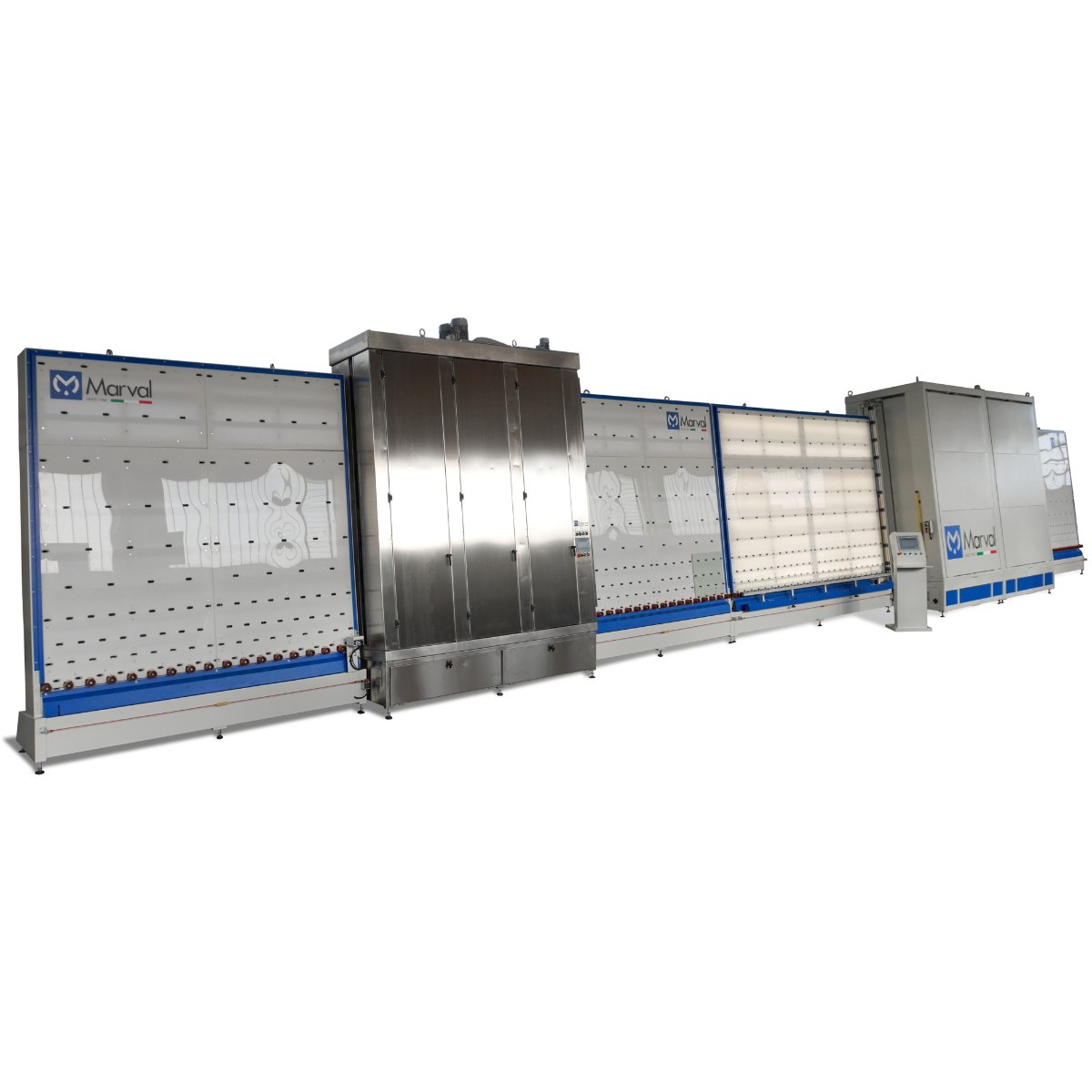

Laminate support panels

Laminated wood panels guarantee a support surface for glass that remains flat and constant over time. This solution makes cleaning easier and avoids any glass microsplinters, which might scratch the following panels, from depositing.

Mobile part opening

The movement of the mobile part designed and made by Marval gives you a 500mm access compartment for the machine, thereby making maintenance and cleaning easier. This feature, combined with the use of laminate panels, means that daily cleaning can be carried out very quickly with a simple jet of air, without taking time away from production.