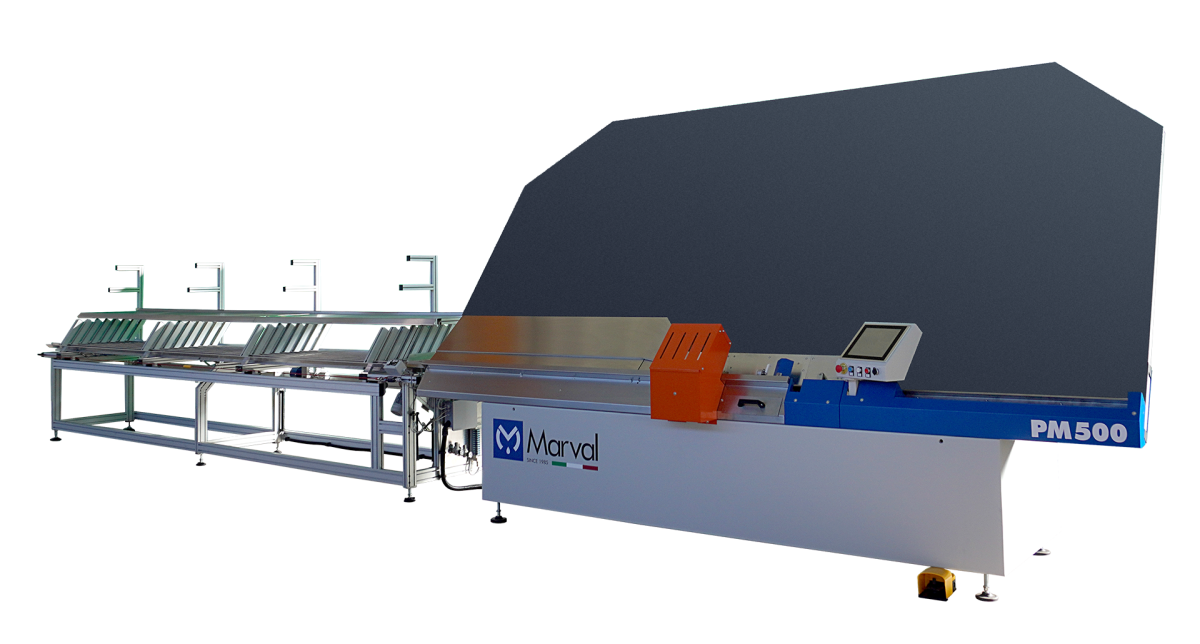

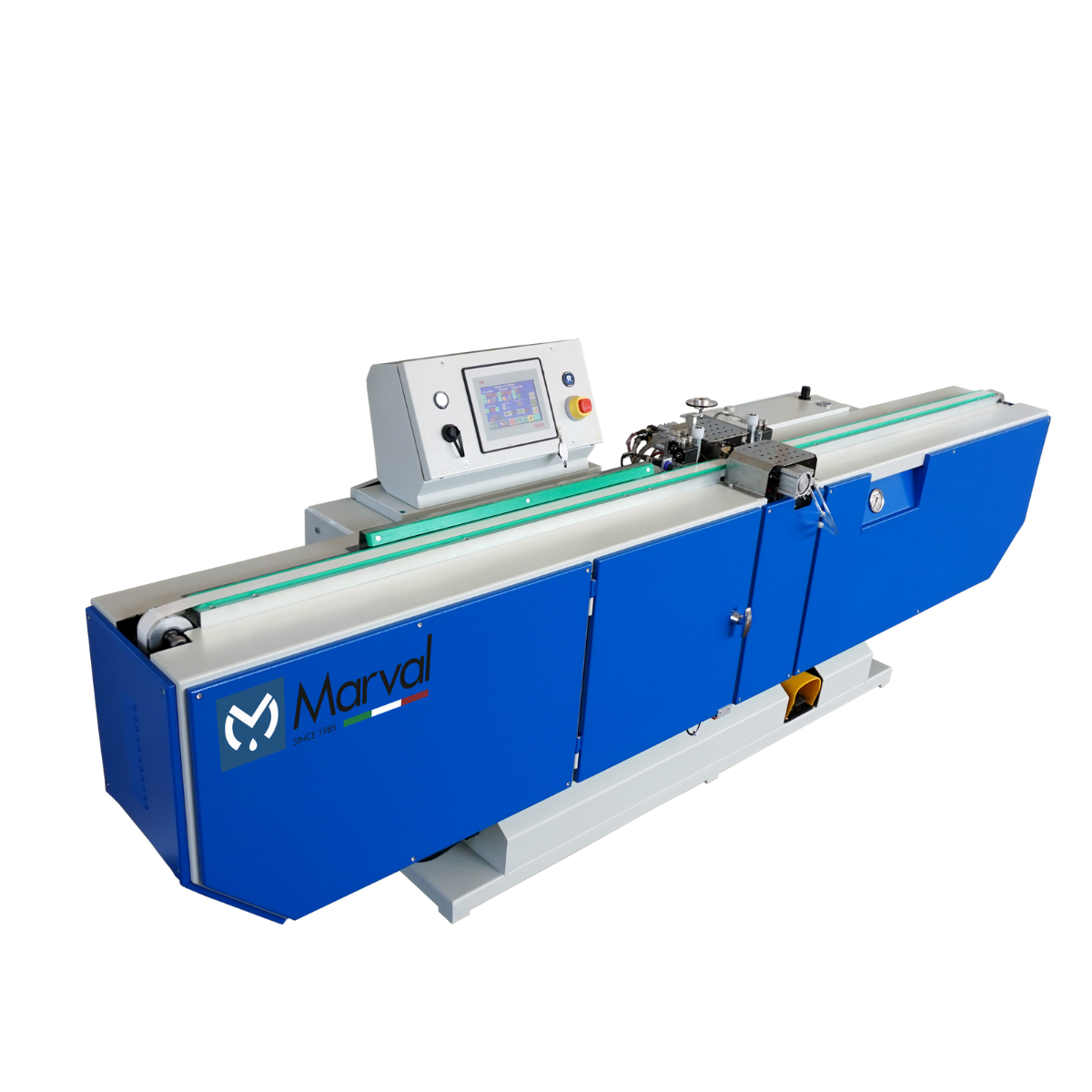

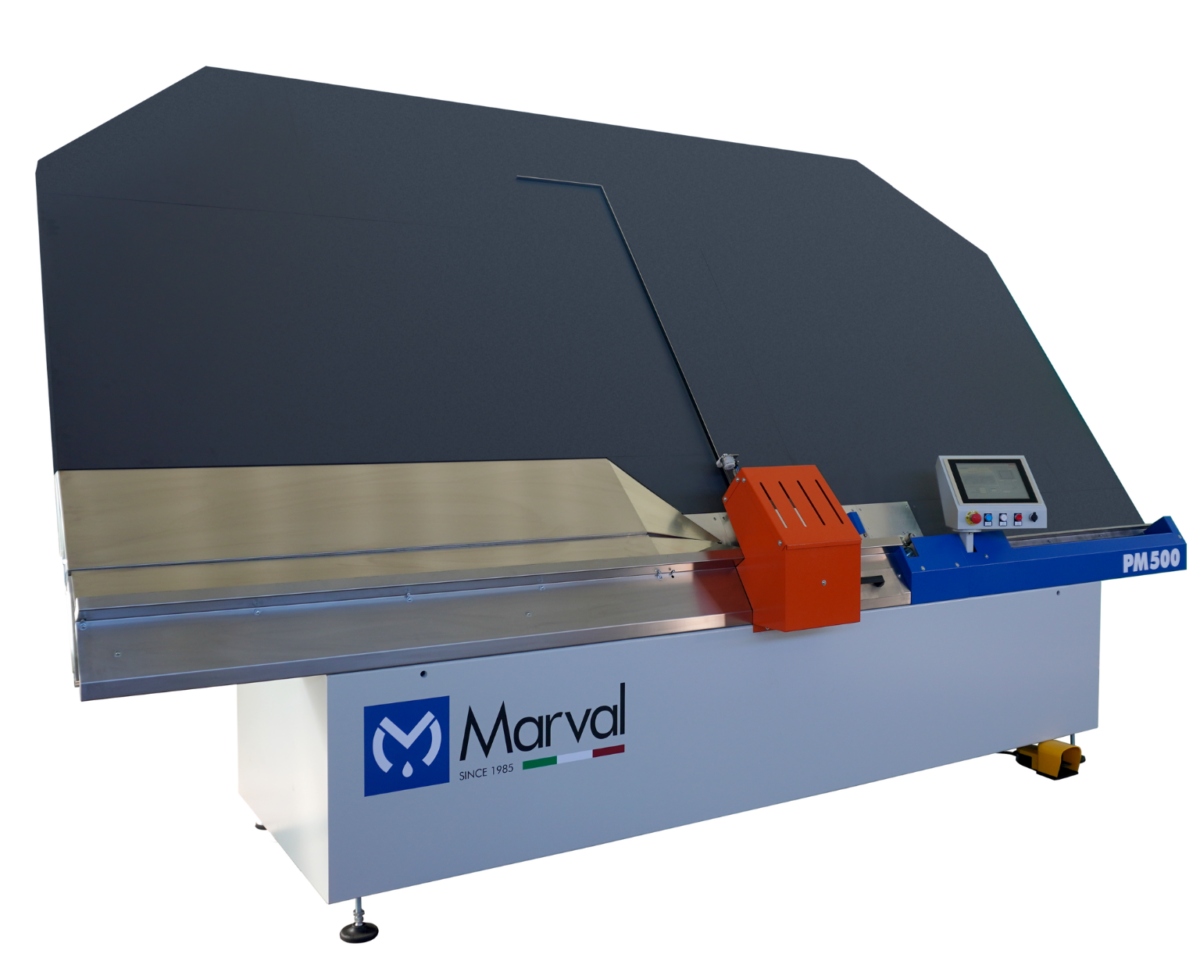

Automatic bending machine “TOP BEND”

The “TOP BEND” automatic profile bender expresses the highest level of technology requested today from worldwide markets for the manufacture of insulating glass frames. The perfect response to meet the needs of companies that want to stand out for their quality and flexibility.

The different configurations available are able to bend various types of spacers in straight or curved shapes.

Simple and compact, “TOP BEND” is ready to execute any operation required for this specific process, achieving considerable recognition for its performance and price-quality ratio.

Bend, curve, punch

The “TOP BEND” automatic bending machine is the perfect solution to:

- bend and calender various types of spacers (even with warm edge);

- work with 6 to 30 mm widths.

The Marval bending machine also has a magazine with seven positions that can either be manual or motorised.

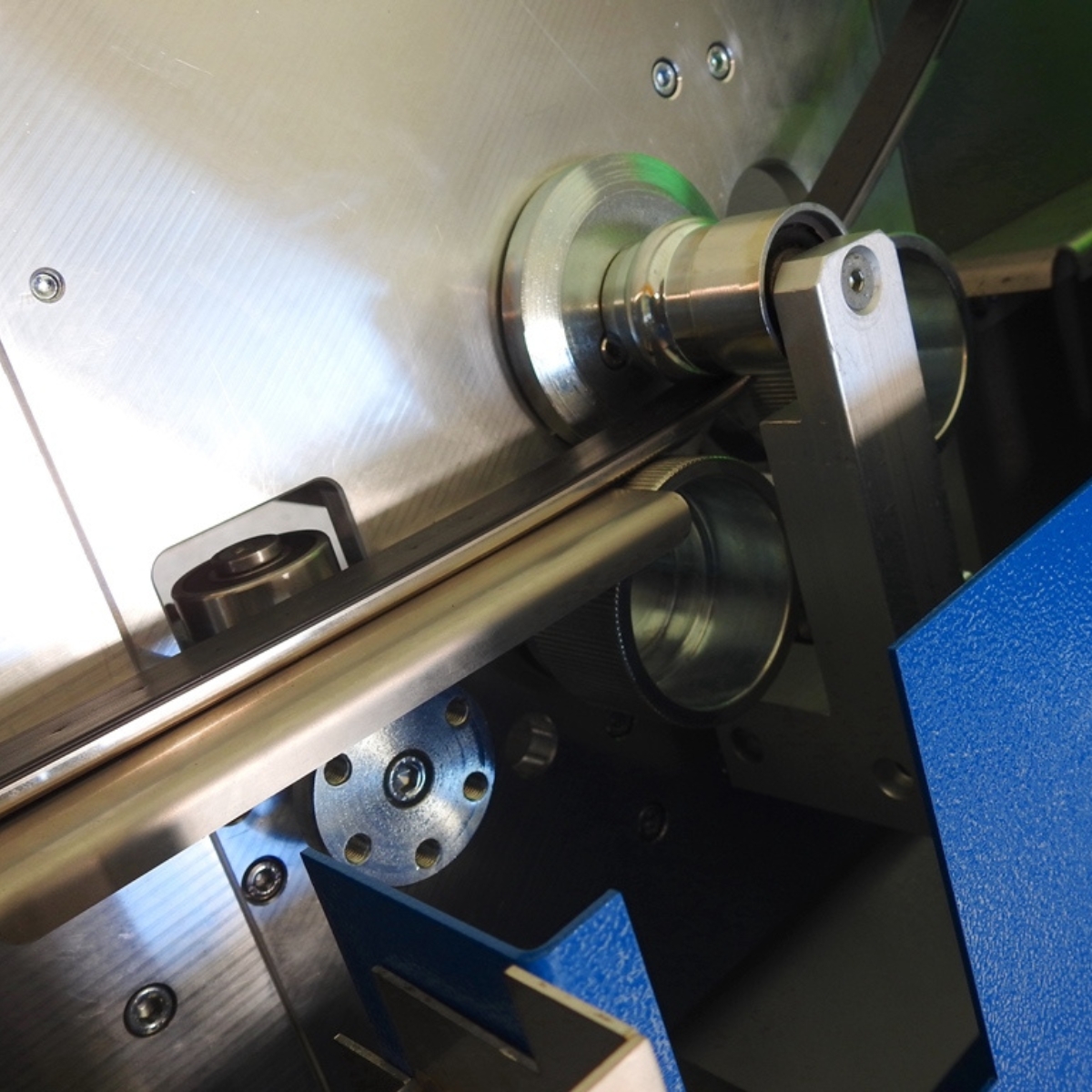

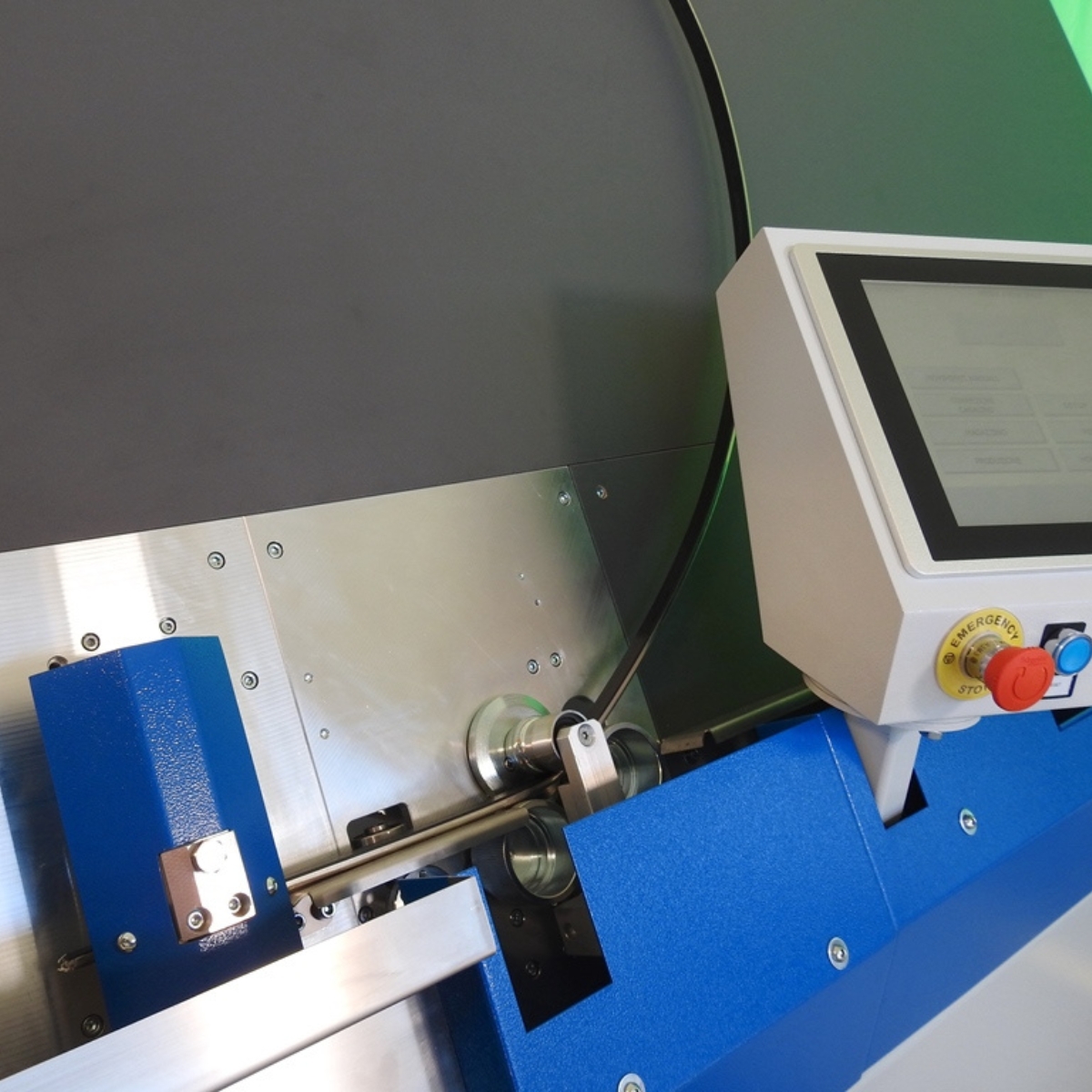

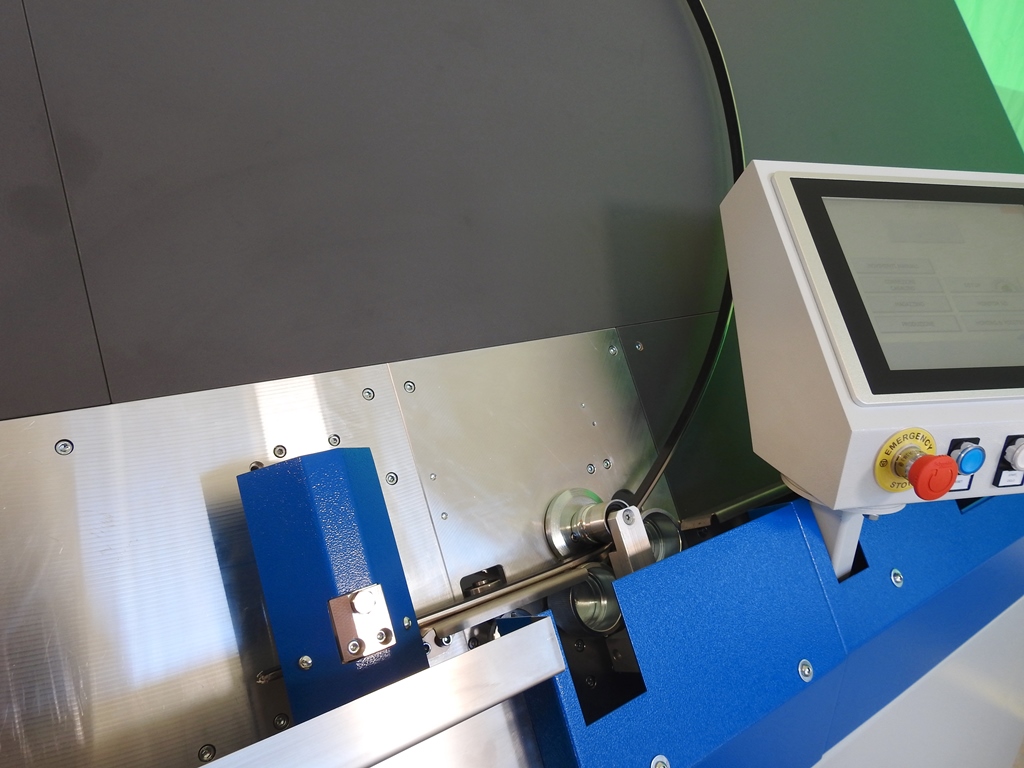

Bending unit

The new bending system, which has been entirely redesigned allows various types of materials and thicknesses to be processed without having to replace the punch. Bending arm movement is motorised for maximum precision even on complex shapes.

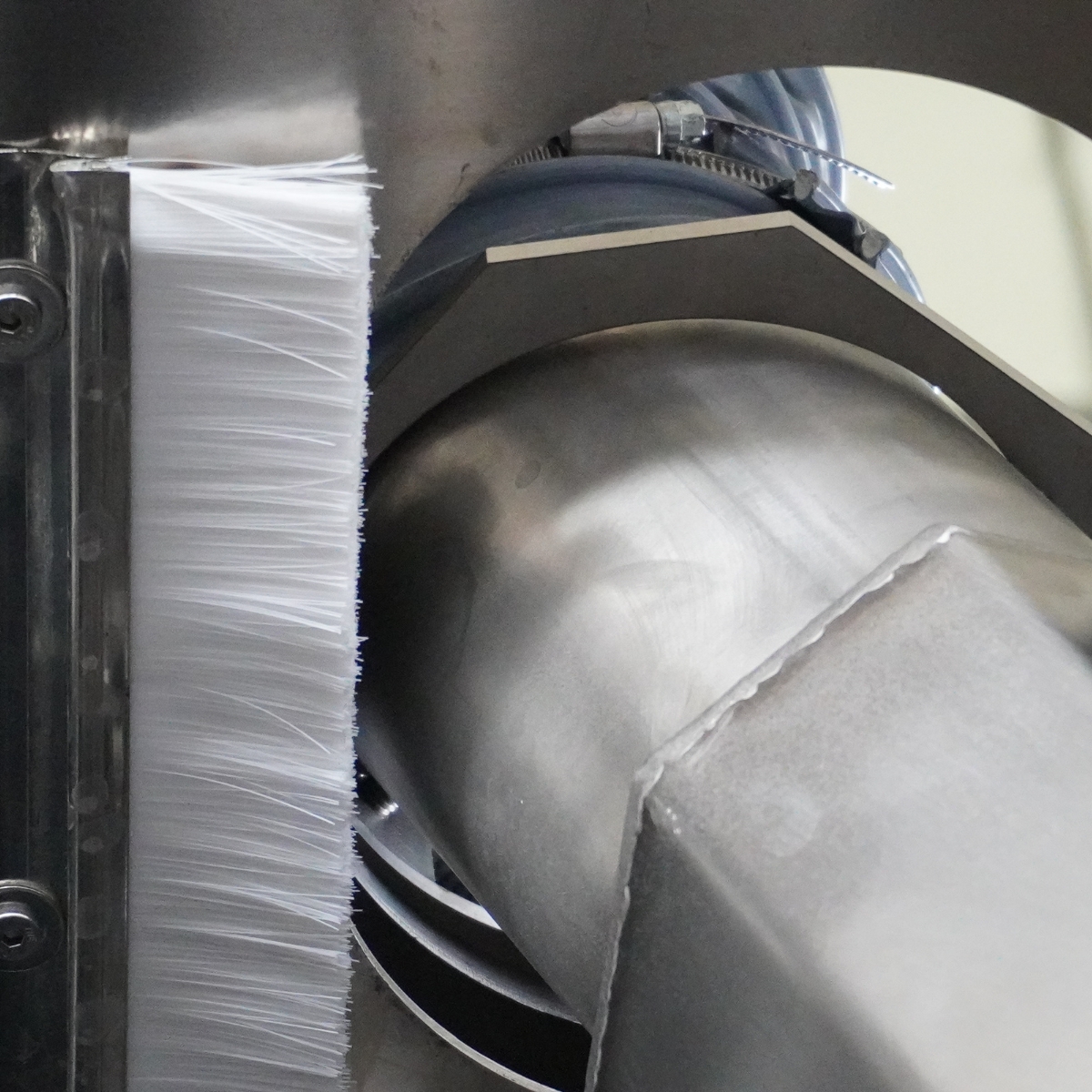

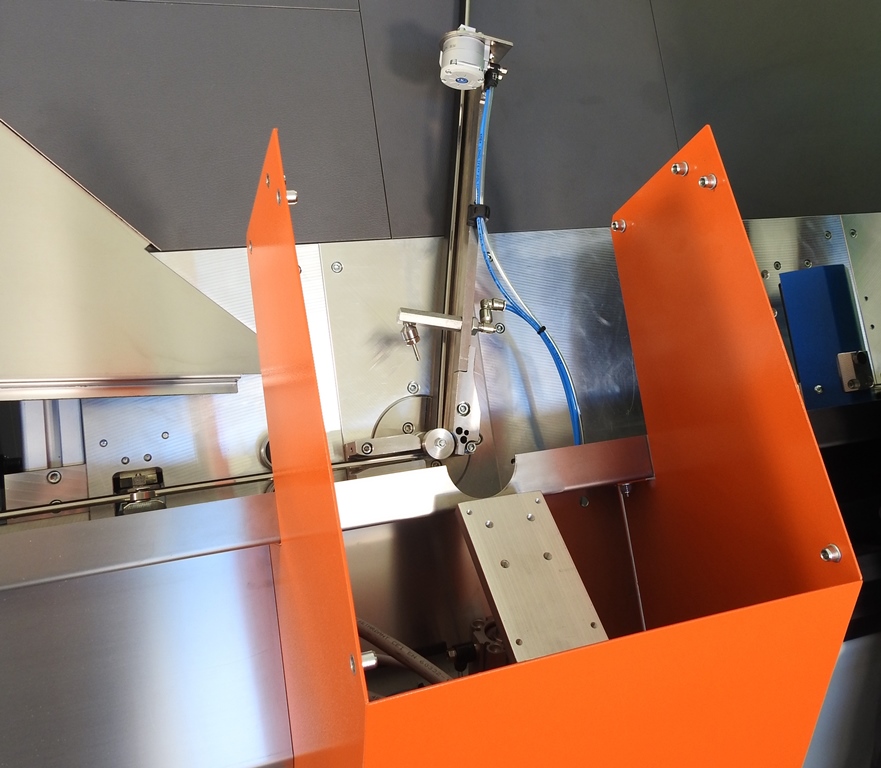

Calender unit

The calender unit, handled via a brushless motor, executes any type of shape, even complex ones.

The machine independently moves the spacer, also via a brushless motor, based on the shapes to be formed.

Spacer magazine

The automatic spacer magazine consists of an aluminium frame with seven positions: each position can hold up to forty spacers, allowing there to be up to 280 spacers available at all times.

Spacer joints

In order to prevent wasting material, the machine automatically optimises the spacers, joining several bars – if necessary – to create a single shape.