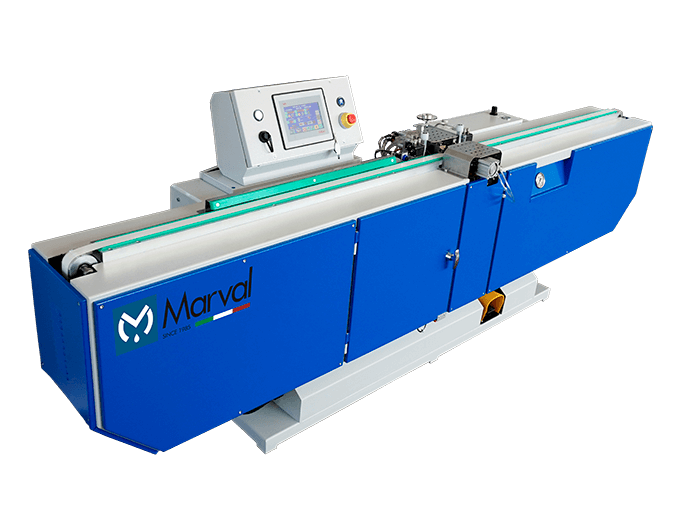

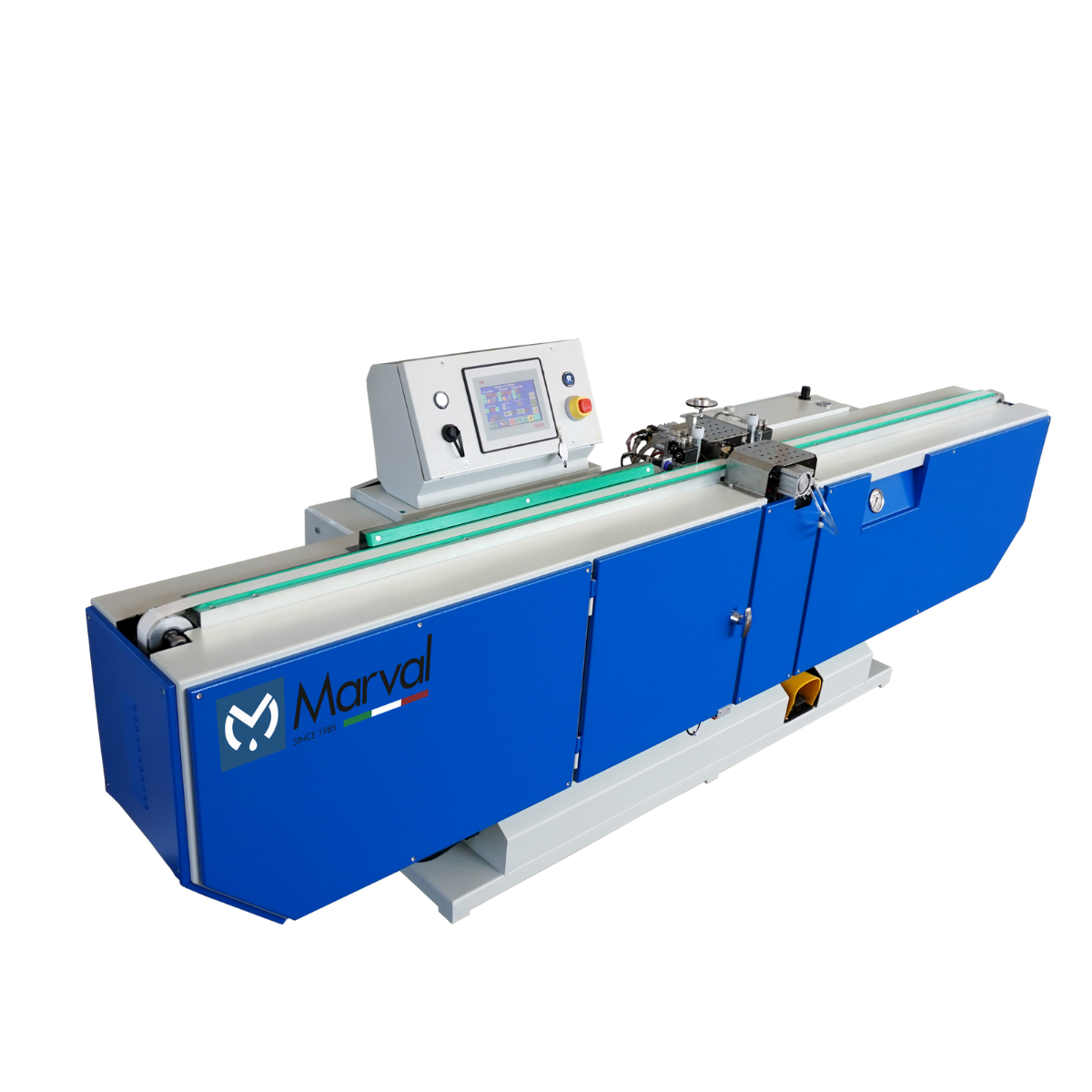

Automatic desiccant filler “TOP DRY”

Using the “TOP DRY” desiccant filler enables the spacers to be filled automatically: the only operation required of the operator is to load and unload the profile.

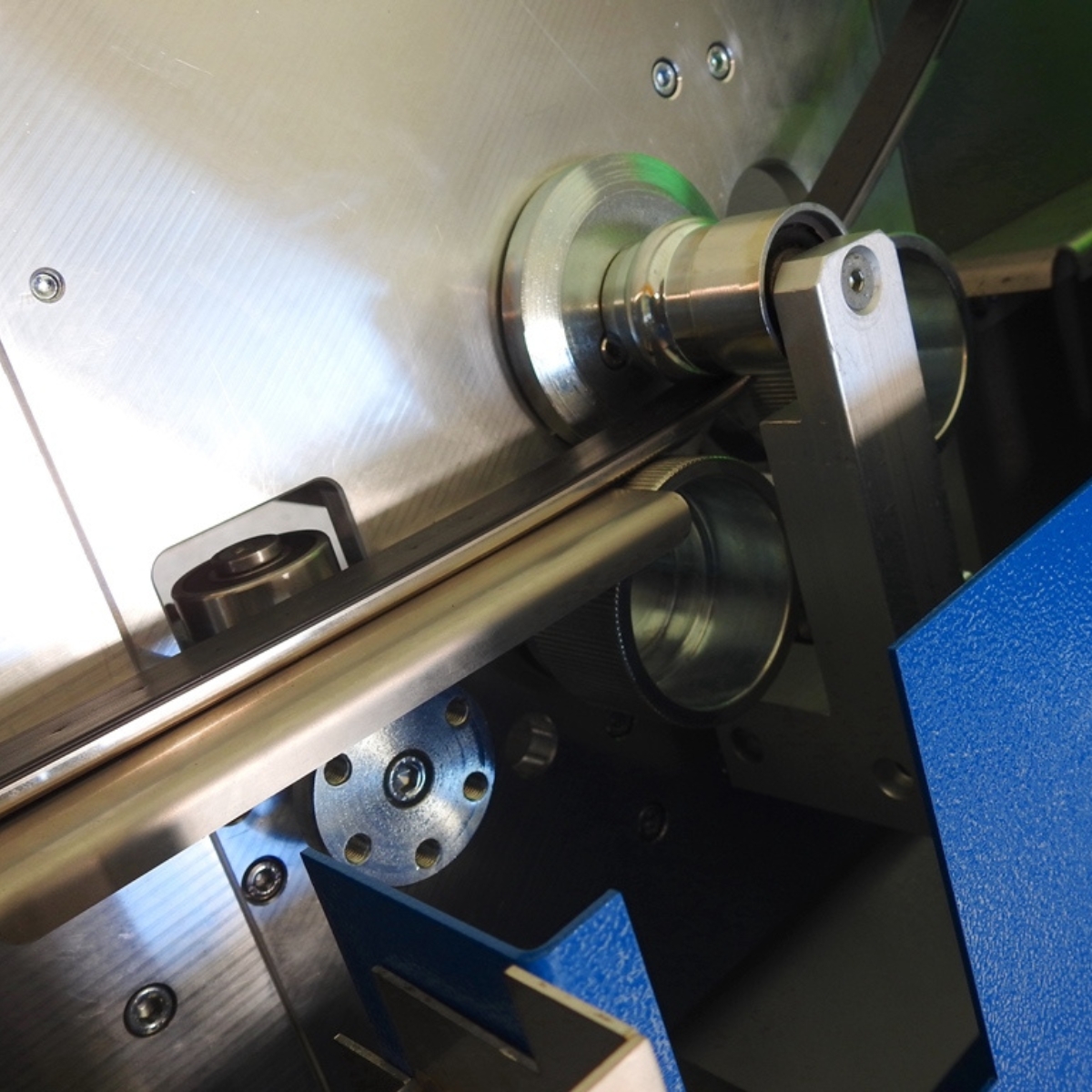

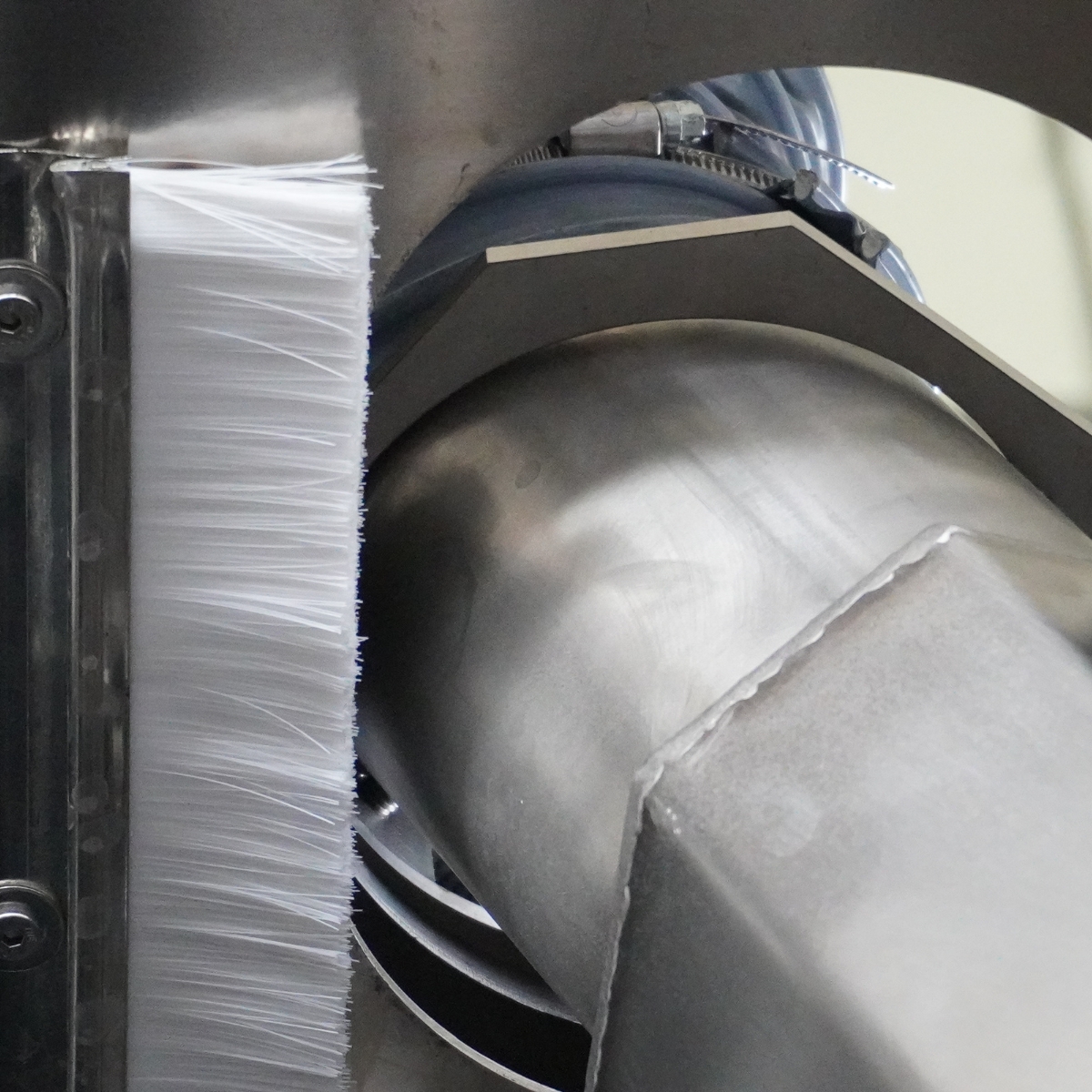

The versatility of this machine makes it possible to process profiles of completely different materials, from aluminium to steel, including the so-called “warm edge” (Thermix, TX.N Pro, Swisspacer Ultimate, Tgi Spacer M, Tgi Spacer Precision, Thermobar, Multitech, Swisspacer Advance, Chromatech Ultra, Thermix Low Psi).

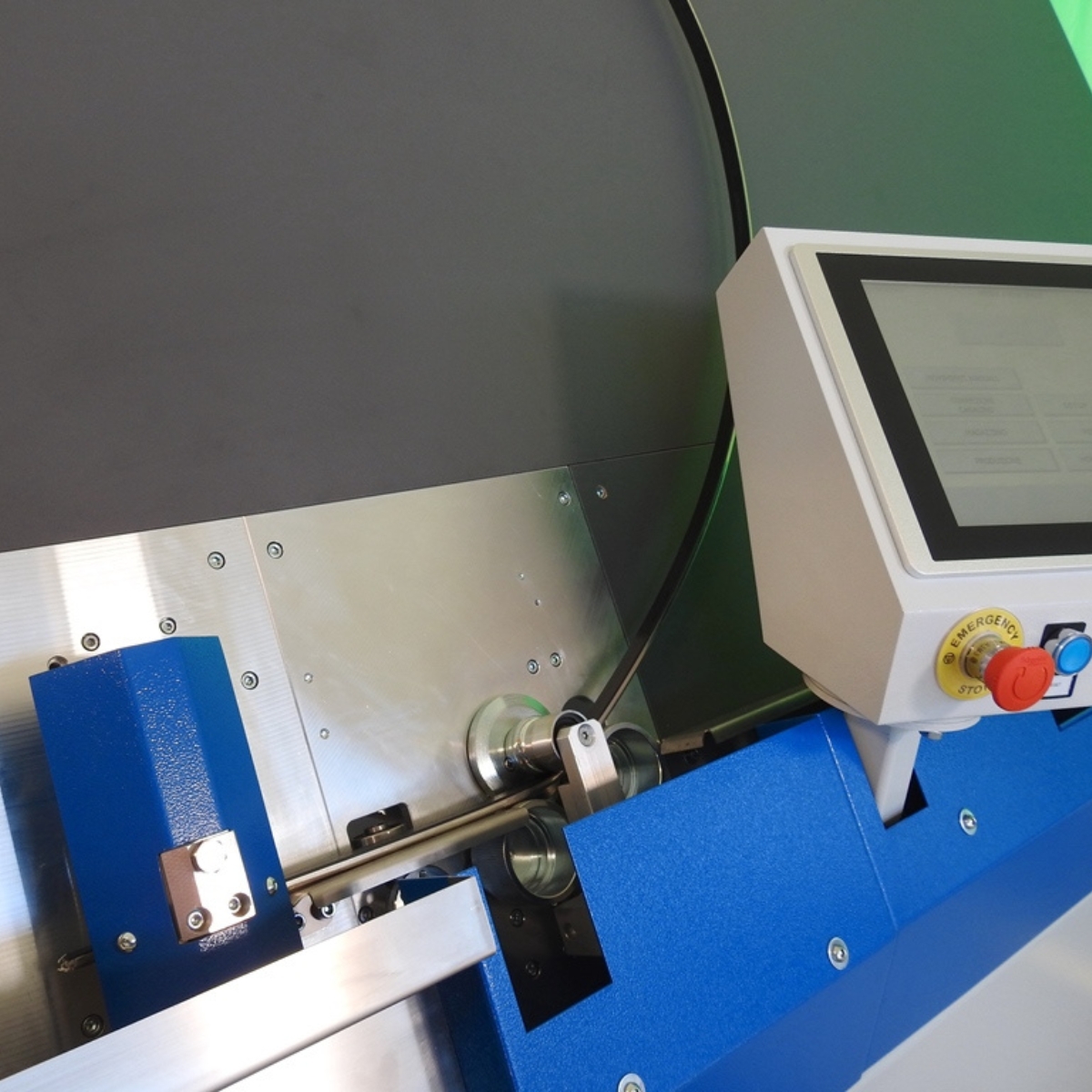

Simply pressing the machine’s start button starts the processing cycle, which entails drilling the holes in the profile, filling them with desiccant and sealing the holes with butyl.

The control panel on board the machine means that the “TOP DRY” is very small.

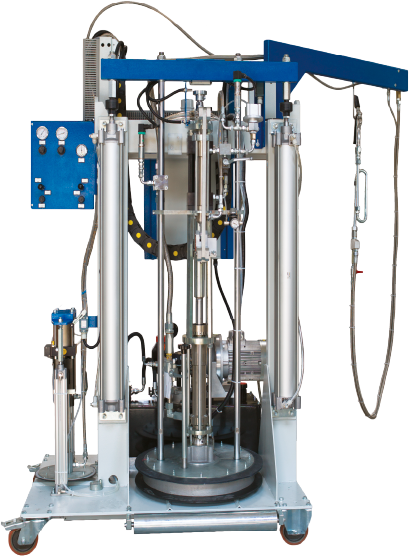

The use of appropriately sized drums, from which the machine automatically takes the desiccant, guarantees excellent autonomy.